Black Annealed Wire vs. Bright Annealed Steel Wire: Key Differences

Low carbon annealed steel wire is a common type of wire used in various industries. It undergoes a heat treatment process called annealing to improve its ductility and softness. The appearance of this wire can vary depending on the specific annealing process used, resulting in two main types: bright annealed and black annealed.

Key Differences:

- Surface Finish: Bright annealed is shiny, while black annealed is matte.

- Production Process: Bright annealed is annealed in a controlled atmosphere, while black annealed is annealed in open air.

- Applications: Bright annealed is used where appearance is important, while black annealed is used where functionality is prioritized.

- Corrosion Resistance: Bright annealed generally has better corrosion resistance than black annealed.

Low Carbon Black Annealed Wire

Black annealed wire is a steel wire that undergoes a process called annealing, where it is heated to a high temperature and then gradually cooled. This process softens the wire, enhances its ductility, and results in a distinctive black color due to surface oxidation. The combination of flexibility and strength makes black annealed wire ideal for various applications.

Applications

- Binding and Tying: The wire’s enhanced ductility and strength are well-suited for binding and tying materials, making it a popular choice in construction and bundling applications.

- Wire Mesh: Black annealed wire serves as a base material in the production of wire mesh products such as fencing, screens, and filters.

- Nails and Screws: It is also used as a core material in certain types of nails and screws, providing the necessary strength and flexibility.

Specifications

- Gauge: This refers to the diameter of the wire, with common gauges being 10, 12, 14, 16, and 18.

- Material: Most black annealed wire is made from low-carbon steel. The carbon content is a key determinant of the wire’s properties, where lower carbon content results in a softer and more ductile wire. Some variations in alloying elements may be present to achieve specific properties.

- Tensile Strength: Tensile strength is the maximum stress the wire can withstand before breaking, typically measured in pounds per square inch (psi) or newtons per square millimeter (N/mm²). This measurement is crucial for ensuring the wire’s durability in various applications.

- Elongation: Elongation indicates the wire’s ability to stretch before breaking, expressed as a percentage of its original length. A higher elongation value reflects greater ductility, making the wire more suitable for binding and tying applications.

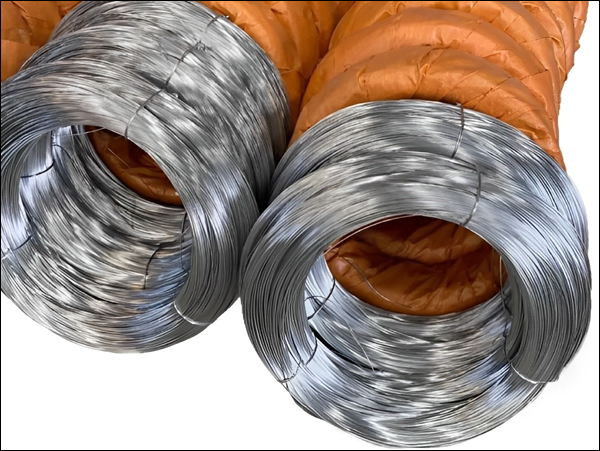

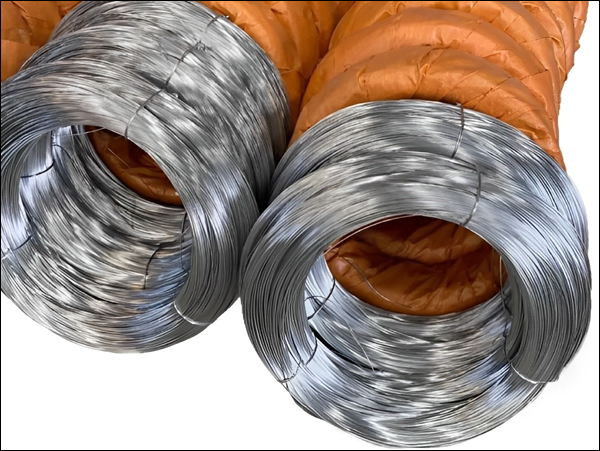

- Coiling: For ease of handling and storage, black annealed wire can be coiled or spooled. The method and size of the coils vary depending on the intended use and the manufacturer’s practices.

- Packaging: The wire is commonly packaged in coils or spools, with protective materials like paper or plastic wrapping to prevent damage during transportation and storage. 5Kg per plastic bag, 10Kg per carton.

Low Carbon Bright Annealed Steel Wire

Material

- Low Carbon Steel: Typically made from low carbon steel, which has good ductility and softness. Common grades include SAE 1006, 1008, and 1010.

- Carbon Content: Generally ranges from 0.05% to 0.25%, which influences the wire's strength and flexibility.

Diameter (Gauge)

- Range: Usually available in diameters from 0.2 mm to 5.0 mm.

- Common Gauges: 10 to 24 gauge, where smaller numbers indicate thicker wire.

Tensile Strength

- Range: Typically between 300 MPa to 600 MPa, depending on the wire's diameter and specific application. This measures the maximum stress the wire can withstand without breaking.

Elongation

- Percentage: Usually between 15% to 30%, which indicates how much the wire can stretch before breaking. Higher elongation means better flexibility.

Surface Finish

- Appearance: Shiny, smooth, and reflective finish due to the annealing process in a non-oxidizing atmosphere.

- Cleanliness: Free from surface defects, rust, and oxidation, making it suitable for applications where aesthetics are important.

Coiling

- Forms: Available in coils or spools for easy handling and storage.

- Coil Size: Coil weights typically range from 1 kg to 500 kg, depending on the specific requirements.

Packaging

- Material: Often wrapped in protective materials such as plastic or paper to prevent damage during transportation and storage.

- Packaging Type: Available in coils, spools, or cut-to-length, depending on customer requirements.

Applications

- Common Uses: Automotive components, household appliances, springs, fasteners, and other products requiring both strength and an attractive appearance.

20 Gauge (0.9mm) Low Carbon Annealed Mild Steel Wire

This finer gauge wire is suitable for more delicate tasks in masonry and other construction applications, offering the same strength and flexibility as thicker gauges but in a more manageable size.

Specifications:

- Gauge: 20

- Diameter: 0.9 mm

- Material: Low carbon mild steel, annealed for enhanced flexibility and durability.